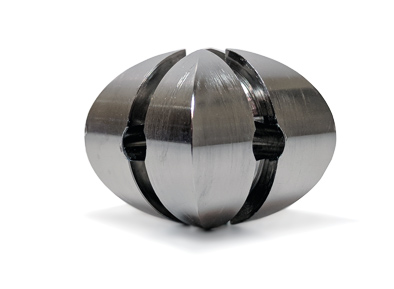

Square Ball Universal Joint Advantages in Steering Applications

Over u-joints with needle bearings:

Larger Load Zone

- Universal joints with needle bearings experience line load fretting on raceways due to continuous vibration, which shortens their service life.

- The SBJ offers a significantly larger load zone than the combined contact area of needle bearings.

- This larger load zone distributes vibrating surface pressure over a broader area, effectively eliminating fretting issues.

Low Starting & Operational Torque Resistance

- The starting rotational torque of a SBJ is very low, with an operating angle range is 0 to 38 degrees.

- Torque is transferred through just three components, minimizing tolerance stackup issues, resulting in consistently smooth movement.

- In contrast, needle bearing u-joints consist of around 100 components, creating tolerance stack-up issues with inconsistent starting and rotational torque values.

- The SBJ’s low and consistent startup torque values provide advantages for autonomous steering applications.

Boot-Sealed Design

- All moving components are fully enclosed, lubricated and protected by the boot seal.

- The boot features a nearly 60% grease fill, making it a maintenance-free joint.

- With an IP68 rating, the SBJ outperforms conventional wiping seals.

Cushion Retaining Pin

- The retaining pin engages with a groove in the square ball, keeping it centered within each yoke.

- An over molded retaining pin absorbs vibrations responsible for NVH issues, making the SBJ operates silently.

- The cushion pin does not transfer torque

Square Ball Universal Joint Patent is Protected by International and US Patents:

- US Patent No. 10,443,661

- China P.R. Application No. 20178000404.2

Ready to Enhance Your Steering Applications?

Discover the unmatched performance and reliability of the Square Ball Universal Joint. Contact us to learn how the SBJ can optimize your system with maintenance-free durability and precision steering control.