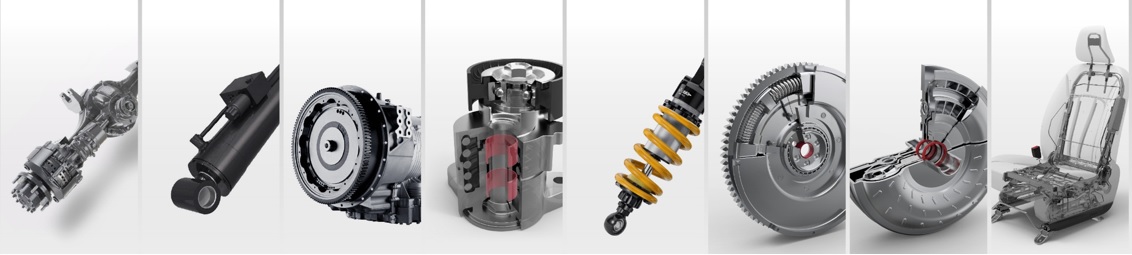

When it comes to vehicle handling and ride comfort, shock absorbers are critical in absorbing road impacts and ensuring that tires maintain firm contact with the ground. However, the efficiency and longevity of shock absorbers depend on the quality of their internal components—especially their bushings. Slide and guide bushings, in particular, play a crucial role in reducing friction, maintaining precise motion and enhancing durability in vehicle suspension systems.

The Functionality of Shock Absorber Bushings

Shock absorber bushings serve as the interface between the moving parts of the suspension system, helping to cushion vibrations and ensure smooth, controlled movement. Slide and guide bushings, in particular, support the linear motion of the piston rod, reducing resistance and preventing metal-on-metal contact that can lead to premature wear.

Unlike conventional bushings, slide bushings allow for controlled axial movement within the shock absorber, ensuring precise alignment as the piston rod moves up and down. Guide bushings, on the other hand, provide stability by preventing lateral movement that could lead to misalignment or uneven wear. Together, these bushings help shock absorbers maintain optimal damping performance, even in demanding driving conditions.

CCTY’s TLA bushing material is designed to meet the rigorous demands of shock absorber applications. With low friction, excellent wear resistance and compatibility with all shock absorber oils, these bushings ensure long-term reliability in high-performance vehicles.

Engineered for Maximum Durability & Performance

The construction of shock absorber bushings directly impacts their longevity and effectiveness. At CCTY, our bushings feature a hardened steel backing with a PTFE-lined inner surface, combining strength with a self-lubricating, low-friction layer. This advanced composition ensures that the bushings maintain smooth operation over time, even under extreme loads and temperatures.

The PTFE lining reduces friction between the piston rod and bushing surface, allowing for precise and efficient movement without the need for additional lubrication. This extends the life of the shock absorber while enhancing vehicle performance with consistent damping characteristics.

In addition to performance benefits, CCTY’s bushings are environmentally friendly and compliant with global regulations. They are lead-free and RoHS-compliant, meeting the increasing demand for sustainable automotive components without compromising on durability or function.

Furthermore, these bushings are engineered to withstand temperature extremes that range from -200°C to 280°C, ensuring reliability in both freezing cold and high-heat environments. With precise manufacturing tolerances, they operate seamlessly in reciprocating sliding applications like shock absorbers, where maintaining clearance fits is crucial to efficiency and longevity.

Enhancing Vehicle Performance with Shock Absorber Bushings

The right bushings don’t just improve the longevity of a shock absorber—they also play a massive role in vehicle performance. The damping system is responsible for managing road impacts, stabilizing the vehicle and ensuring predictable handling. When equipped with CCTY’s advanced slide and guide bushings, shock absorbers perform more efficiently—delivering a superior driving experience. These bushings help absorb vibration and movement with minimal resistance, ensuring that the vehicle maintains stability and comfort regardless of road conditions.

By incorporating slide and guide bushings with PTFE linings, our shock absorbers:

- Improve Ride Comfort: By reducing friction and maintaining precise movement, these bushings help minimize vibrations and jolts from uneven road surfaces—creating a smoother and more enjoyable driving experience.

- Enhance Vehicle Stability: Guide bushings prevent lateral movement of the piston rod, ensuring precise handling, reduced body roll and improved steering response—especially during sharp turns or sudden stops.

- Extend Service Life: With high wear resistance and self-lubricating properties, these bushings are engineered to withstand extreme conditions, which reduces maintenance costs and prolongs vehicle reliability.

- Support Lightweight, Compact Designs: Modern vehicles demand lightweight components that contribute to fuel efficiency without sacrificing durability. CCTY’s bushings provide a compact form factor while maintaining structural integrity, making them ideal for modern automotive designs.

- Maintain Performance in Harsh Conditions: With resistance to extreme temperatures and compatibility with all shock absorber oils, these bushings are built to perform in the toughest environments—from subzero climates to high-speed, high-heat applications.

By integrating high-quality slide and guide bushings, OEMs can ensure that their shock absorbers perform consistently across a wide range of operating conditions. The ability to maintain precise motion while minimizing wear and friction leads to fewer performance issues and longer service intervals. This not only benefits the end user in terms of ride quality but also improves the overall value of the vehicle by reducing repair and replacement costs.

Choosing the Right Bearing for Robotic Applications

Choosing the right bearing for an industrial robotic arm requires a thorough understanding of the system’s specific demands, with engineers carefully evaluating several key factors to ensure optimal performance.

The type and magnitude of loads—radial, axial or moment—that the bearing will encounter is a major factor to consider during the design process. Precision requirements must also be determined to ensure the bearing meets the necessary level of accuracy for the task at hand. Environmental factors, such as temperature, vibration and contamination levels, also play a critical role in the bearing’s performance and durability. Additionally, space constraints like available design space and weight restrictions must be factored into the decision-making process to achieve an optimal balance between functionality and efficiency.

Collaborating with bearing experts early in the design process is critical, as this enables the development of highly tailored solutions that can maximize the performance and longevity of robotic arms. Application-specific adjustments, such as customized preload settings or advanced materials, further enhance the suitability of bearings for demanding robotic tasks.

Driving Innovation in Shock Absorber Technology

A vehicle’s ride quality and handling are directly influenced by the performance of its shock absorbers, and at the heart of that performance are high-quality bushings. Slide and guide bushings engineered with precision not only support the movement of the piston rod but also enhance the entire suspension system’s ability to absorb shocks efficiently.

With CCTY’s advanced PTFE-lined shock absorber bushings, OEMs can confidently design vehicles that offer better control, reduced wear and longer-lasting performance. Whether for passenger cars, heavy-duty trucks or high-performance vehicles, CCTY’s bushing solutions provide a maintenance-free, high-durability option that ensures shock absorbers function at their best throughout the life of the vehicle. By continuously innovating in motion control solutions, CCTY remains a trusted partner in delivering cutting-edge technology for the automotive industry.

Stay Up-to-Date on Motion Control

CCTY’s monthly newsletter covers advancement in motion control along with tips for finding the optimal solution for your application. Join the mailing list today to stay up-to-date on advancements in motion control, product information and CCTY happenings.