Every component in the automotive industry must be designed for durability and optimal performance. Automotive bushings play a large role in reducing friction, controlling motion, and extending vehicle lifespan. At CCTY, we specialize in manufacturing high-quality automotive bushings tailored for OEMs and Tier-1 suppliers worldwide, ensuring smooth, reliable operation across vehicle systems.

Why Automotive Bushings Are Essential

Automotive bushings serve as key interfaces between moving parts, absorbing vibration, reducing noise (NVH), and minimizing wear. Their presence enhances vehicle comfort, safety, and performance by facilitating controlled motion and preventing metal-to-metal contact. Whether in seating assemblies, suspension components, or shock absorbers, quality bushings are foundational to vehicle reliability.

Automotive Bushing Applications Across Vehicle Systems

CCTY manufactures a broad range of automotive bushings designed for specific vehicle applications:

Seat Recliner, Frames & Headrest Bushings

Our seat bushings provide smooth, quiet operation in reclining mechanisms, armrests, and adjustable headrests. Built with PTFE-lined, self-lubricating surfaces and steel-backed construction, these bushings reduce friction and wear, contributing to interior comfort and long-term durability.

Bushings for Seat Frames and Headrests

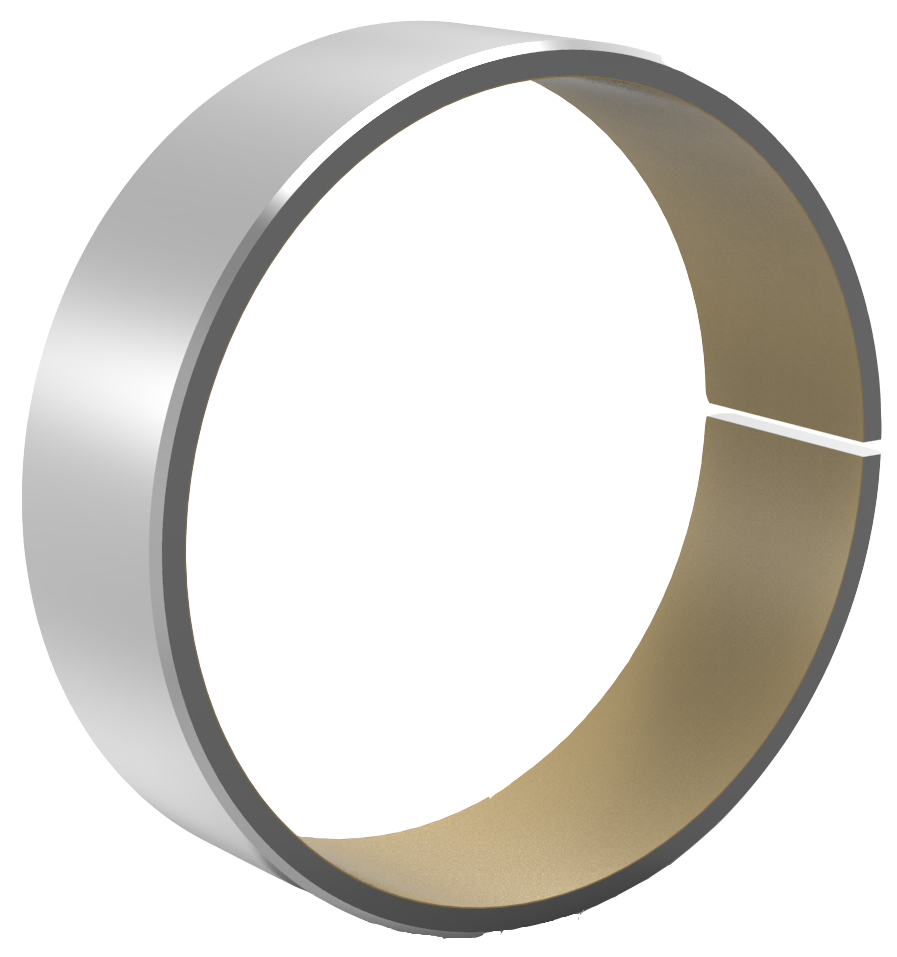

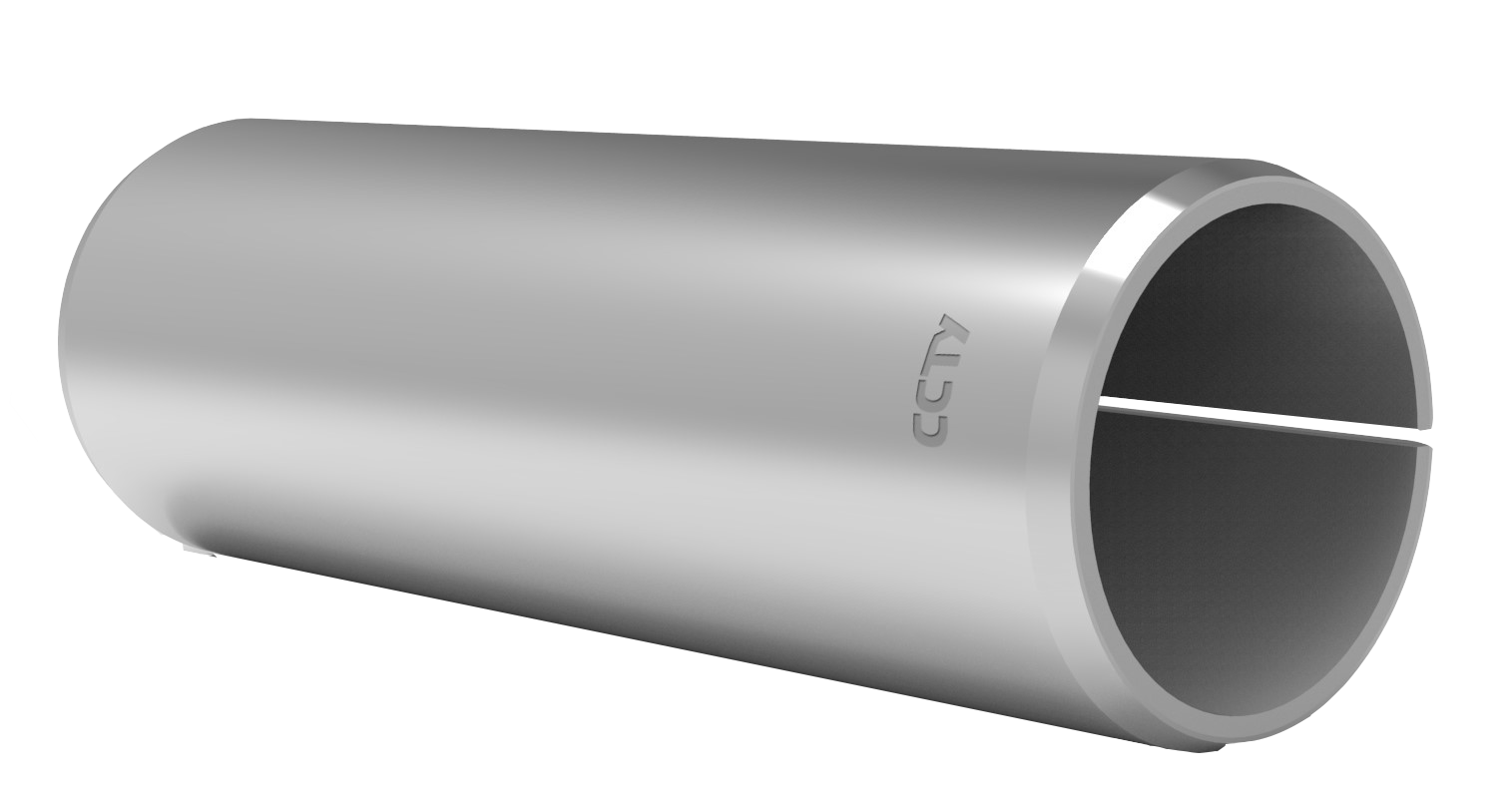

TSA – available in metric and inch sizing – is a versatile bushing that is used in seat frame, headrest and armrest applications.

The bushing features surface PTFE and additives, porous bronze and low carbon steel backing. This material composition results in low friction and excellent wear resistance, which provides a long operation life.

Belt Tensioner Bushings

Integral to accessory drive systems, belt tensioner bushings prevent metal-on-metal contact and help maintain proper belt tension. The TFA bushing is manufactured with steel and PTFE overlays – optimizing performance under various temperature and load conditions while reducing NVH.

TFA is a versatile bushing that is used in belt tensioners. It features a carbon steel backing, sintered porous bronze and a PTFE composite polymer.

- Minimized operational bushing harmonic noise and harshness levels

- Improved cantilevered edge loading wear resistance

- Maximized polymer overlay for dampening serpentine belt forces and vibration

- Unique polymer bushing structure that generates less working energy on the tensioner system

Shock Absorber Bushings

Smooth suspension depends on high-quality shock absorber bushings. CCTY’s slide and guide bushings feature hardened steel backing with PTFE lining, offering excellent resistance to wear. They are engineered to perform reliably across extreme temperatures ranging from –200 °C to 280 °C.

CCTY’s TLA bushing material is specifically designed to be used in linear motion and reciprocating sliding applications, and compatible with all types of shock absorber oils and does not swell. It presents low friction over the entire life of the bushing. The environmentally-friendly material has excellent wear resistance even with inadequate lubrication. Slide and guide bearings from CCTY are:

- Maintenance-Free

- Lead-Free

- Temp Range -200°C to 280°C

A full range of shock absorber bearings, eyelets and bushings are available from CCTY.

Torque Converter Bushing

CCTY manufactures torque converter bushings designed to minimize friction and wear for rotational and linear motion.

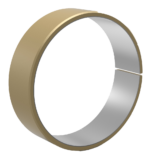

The TOA bushing features a carbon steel backing with sintered porous bronze impregnated with a PTFE composite polymer.

- Self-lubricating material results in low friction and excellent wear resistance giving a long life

- Excels in wiper applications by supporting bearing load, speed and environmental temperatures

Dual Mass Flywheel Bushing

Featuring carbon steel backing, sintered porous bronze and PTFE composite polymer, the TFA bushing has optimized friction and wear resistance for radial and thrust cyclical undulations improving dual mass flywheel performance with:

- Decreased operational harmonic noise and harshness levels

- Lightweight and compact design

- Enhanced lubrication to reduce system wear and extend design life

- Unique polymer structure that minimizes application friction

Windshield Wiper, Hinge and Trunk Bushings

The TSA bushing features a carbon steel backing with sintered porous bronze impregnated with a PTFE composite polymer.

- Self-lubricating material resulting in low friction and excellent wear resistance giving a long life

- Excels in wiper applications by supporting bearing load, speed and environmental temperatures

- Available as cylindrical, flanged, and thrust for trunk and hinge applications

Custom Automotive Bushings for OEMs and Tier-1 Suppliers

CCTY provides a comprehensive range of automotive bushings. We partner closely with OEMs and Tier-1 suppliers to engineer bushings that meet exact specifications—tailoring geometry, materials, and lubrication features for every unique vehicle application.

Custom options include:

- Material selection (PTFE, bronze, steel-backed composites)

- Various shapes: cylindrical, flanged, thrust designs

- Performance considerations for load capacity, wear resistance, and environmental factors

Key Benefits of CCTY Automotive Bushings

Automotive bushings from CCTY provide:

- Extended Service Life: Advanced materials and self-lubricating designs minimize wear and maintenance needs.

- Reduced Noise and Vibration: PTFE-lined surfaces provide smoother, quieter operation across vehicle systems.

- High Temperature and Chemical Resistance: Engineered to withstand extreme temperatures and exposure to automotive fluids.

- Global Manufacturing and Logistics: With 190,000 m² of production space and five global warehouses, CCTY supports just-in-time delivery worldwide.

- End-to-End Engineering Support: From initial concept to full-scale production, engineering experts provide comprehensive technical assistance.

Automotive Bushings and Complete Motion Control Solutions

A significant advantage of partnering with CCTY is access to a full range of motion control components beyond bushings – including bearings, ball joints and tie rods, allowing automotive engineers to source critical parts from a single supplier, simplifying supply chain management.

CCTY’s engineering team is here to help. Reach out today to start a conversation – your next innovation starts with a single step.