Original equipment manufacturers are constantly looking to reduce costs and streamline production. One way to accomplish both goals is through bearing assemblies.

A bearing assembly is when two or more individual components, such as a tie rod and rod end, are fully assembled at the manufacturer and shipped to the OEM as one piece. Bearing assembly reduces cost in two ways:

- Individual components are produced by the same manufacturer, so the overall production cost of individual parts can benefit from a volume purchase discount.

- One step on the production line is eliminated, which speeds internal assembly and lowers manufacturing costs.

Plus, assemblies can be easier for end users to install for replacement components – and OEM buyers have fewer vendors to manage.

What types of assemblies can bearing manufacturers supply?

It’s wise to talk to your bearing supplier about how the assembly will be used. Depending on the application, full units with bearings and bushings pre-installed can be shipped based on individual needs. For example,

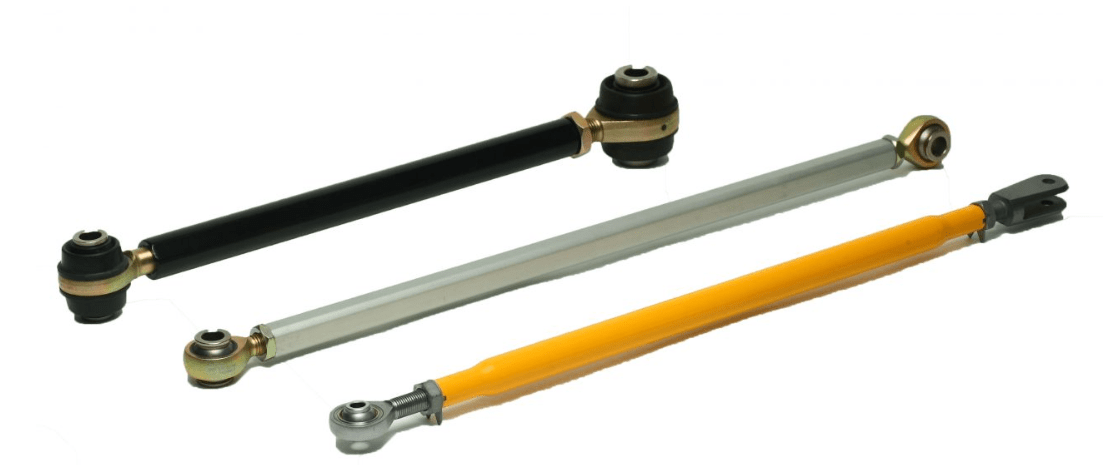

- Steering Linkages

- Ball Joint Assemblies

- Rod End Assemblies

- Bearing Connectors and Bearing Housings

- Rod End and Tie Rod Assemblies

How to Assess a Bearing Assembly Manufacturer

As with all partnerships, it has to be a mutually beneficial relationship. You need a manufacturer who is familiar with total production of the components, the OEM’s construction process and the end product. A bearing manufacturer must also be able to flex lines to accommodate different runs in their plant.

Make sure that your partner is ISO certified, has engineers on staff to review prints with your team and has quality assurance programs in place.

As with all new bearings, test the assembly process with sample parts.

What expenses should an OEM expect?

OEMs may incur tooling costs that are specific to the application. However, the savings generated by using assemblies will greatly exceed the initial cost.

The Bottom Line

When bearing assemblies meet testing and product requirements they are cost- and time-saving alternative to internal assembly.