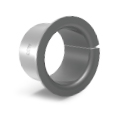

- The physical construction of belt tensioner bushings include low carbon steel metal backed layer with a PTFE self-lubricating attached composite

- Belt tensioner bushings either have the PTFE sintered to the bushing or a bonded PTFE tape liner

- Due to the high-temperature working environment, a sintered PTFE bushing is preferred for its increase stability.

Belt tensioner bushing functionality

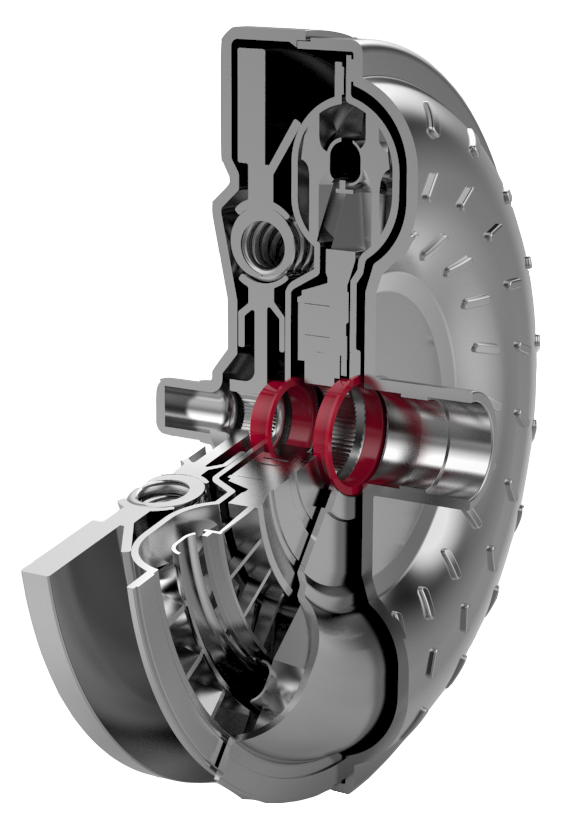

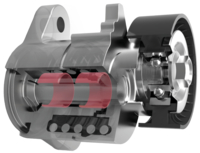

Automotive belt tensioners play an important role in a vehicle’s operational reliance and driver comfort. It powers the steering, air conditioning, alternator and water pump. Bushings are just one component in the belt tensioner system, but they are vital in maintaining a functional accessory system and reducing NVH – noise, vibration or harshness.

Belt tensioner bushings are found between the arm and spring housing, and are used to prevent metal-to-metal dynamic contact. They enable power to transfer efficiently, as well as permit the pulleys to rotate smoothly, and maintain proper tension and alignment.

Composition belt tensioner bushings

In order to handle varying temperature extremes and high-frequency oscillation loads, belt tensioner bushings are constructed using carbon steel, bronze interstructure and a self-lubricating overlay of PTFE composite, sometimes referred to by the brand name Teflon®.

This architecture provides the most secure method of PTFE bonding to the metallic backing, properly allowing sufficient housing assembly and good retention.

What OEMs look for in belt tensioner bushings

Original equipment manufacturers look for RoHS-compliant material that is optimized for friction, wear resistance, high-frequency oscillation performance and long life. The bushing composition must also be highly stable and durable when operating under fluctuating loads and changing temperatures.

Oftentimes, bushings are custom produced to meet product-specific application requirements, such as a unique structure that generates less working energy placed upon the tensioner system.

Partnering with a bushing expert at the start of a project allows for a technical discussion on the belt tensioner bushing’s use durability requirements and how to enhance the overall performance capability.

The bottom line

Belt tensioner bushings are an important component in maintaining reliability, performance life, low NVH and ensuring an efficient transition of power.