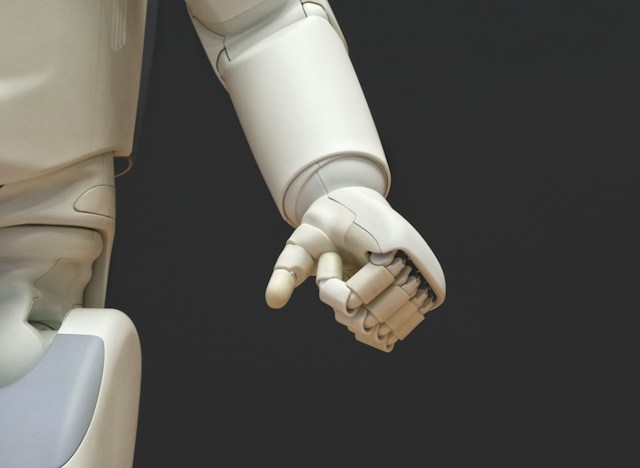

Fluid Movement

As a leading manufacturer of precision bearings and motion-control solutions for robotics and humanoid applications, CCTY’s crossed roller bearings, rod ends, and custom assemblies deliver high accuracy, smooth motion, and long life. Our product line supports OEMs in collaborative robots, industrial automation, and advanced humanoid platforms worldwide with:

- Fully Customized Design: Our bearings are tailored to meet the unique specifications of each customer.

- Simplified Assembly Process: Designed to precise torque and clearance requirements, assemblies speed up production and save time and resources as companies scale operations.

- In-House Testing: CCTY conducts rigorous performance testing on all custom-designed products, ensuring they meet the highest standards of quality and reliability.

Space-constrained Applications

By minimizing the outer diameter through reduced bore size, our robotic bearings are ideal for compact and lightweight designs without compromising performance. This space-saving feature is crucial for high-precision applications where every millimeter counts, such as in humanoid hands and surgical robots.

Optimizing the bearing dimensions without sacrificing load capacity or precision allow for greater flexibility in design and integration.

Learn About CCTY’s Robotic Sizing| Bearing Type | Size | Application |

| Crossed Roller Bearing | Bore Size ≥ 10mm | Rotary Actuators Output |

| Flexible Ball Bearing | Bore Size ≥ 20mm | Rotary Actuators Input |

| Bushings | Bore Size ≥ 2.5mm | Humanoid Robotic Hands, Rotary Actuators, Linear Actuators & Linkages |

| Spherical Plain Bearings, Rod Ends and Linkages | Bore Size ≥ 3mm | Linear Actuators, Rod Ends |

| Four Point Contact Ball Bearing | Bore Size ≥ 20mm | Linear Actuators |

| Angular Contact Ball Bearing | Bore Size ≥ 20mm | Linear Actuators |

Crossed Roller Bearing Design Considerations

Explore the critical role that crossed roller bearings play in facilitating the smooth and precise movement of humanoid robots, including key benefits and important considerations for designing crossed roller bearings in complex robotic systems.